|

Sugar River

Hydro Project, Newport, NH; S. Morgan Smith Francis turbine rebuilt and put

on line in 1986 for owner William Ruger, Jr. |

Click photo to enlarge,

use back button to return to page |

Sugar River

generator, 125 kW, direct connect, synchronous, General Electric. |

Click photo to enlarge,

use back button to return to page |

|

Sugar River

switchgear built by Summit |

Click photo to enlarge,

use back button to return to page |

Eel screen

Voluntarily made by Summit installed during eel downstream migration in

fall. |

Click photo to enlarge,

use back button to return to page |

|

Flygt

turbine/generator obtained by Summit from an abandoned hydro site in PA. |

Click photo to enlarge,

use back button to return to page |

Another benefit

of hydro: plastic debris removed from the river and properly disposed of.

These two barrels of waste can be collected in a single day. The wood debris

is composted. |

Click photo to enlarge,

use back button to return to page |

|

The solid

concrete dam at Wyre Wynd Hydro (built in the 1920's) was showing some

uniform erosion of the downstream surface. Consequently, during 2009 the dam

was resurfaced employing a 3-step process: 1) pressure wash old concrete

surface, 2) lay reinforcing steel, and 3) shoot approx. 6" thick concrete

utilizing Gunite placement process. |

Click photo to enlarge,

use back button to return to page |

September 2009 forebay was

drained and stone walls were Gunite finished to eliminate leakage and strengthen

walls. |

Click photo to enlarge,

use back button to return to page |

|

The resurfacing project

involved 7 men working 7 weeks, 450 man hours of pressure washing, 242 yards

(35 truck loads) of concrete, 2 tons of epoxy coated rebar. Job completed

11/2/09. |

Click photo to enlarge,

use back button to return to page |

The Gunite process consists of

dry concrete mix blown through a hose with water introduced at the nozzle.

Adding minimal water at the last moment results in zero slump and a very

strong finished product. |

Click photo to enlarge,

use back button to return to page |

|

A-1 Gunite Construction, Inc.

employee Kevin shoots a section.

The Gunite process eliminates

the cost of form work that would be necessary with poured concrete. |

Click photo to enlarge,

use back button to return to page |

Duncan smoothes and levels the

concrete to minimize erosion from flowing water. |

Click photo to enlarge,

use back button to return to page |

|

SHI employees, Rick (left) and

Bob are identical twins who keep things running smoothly at the hydros. Who

do you think is the harder worker on this day? |

Click photo to enlarge,

use back button to return to page |

Photo shows newly resurfaced

dam and new eel ladder voluntarily installed October 2009 in conjunction

with DEP. Eels climb the netting and swim into the impoundment through the

white pipe. |

Click photo to enlarge,

Click photo to enlarge,

use back button to return to page |

|

Newly resurfaced dam and two

new eel net ladders, 11/3/09. |

_small.jpg)

Click photo to enlarge,

use back button to return to page |

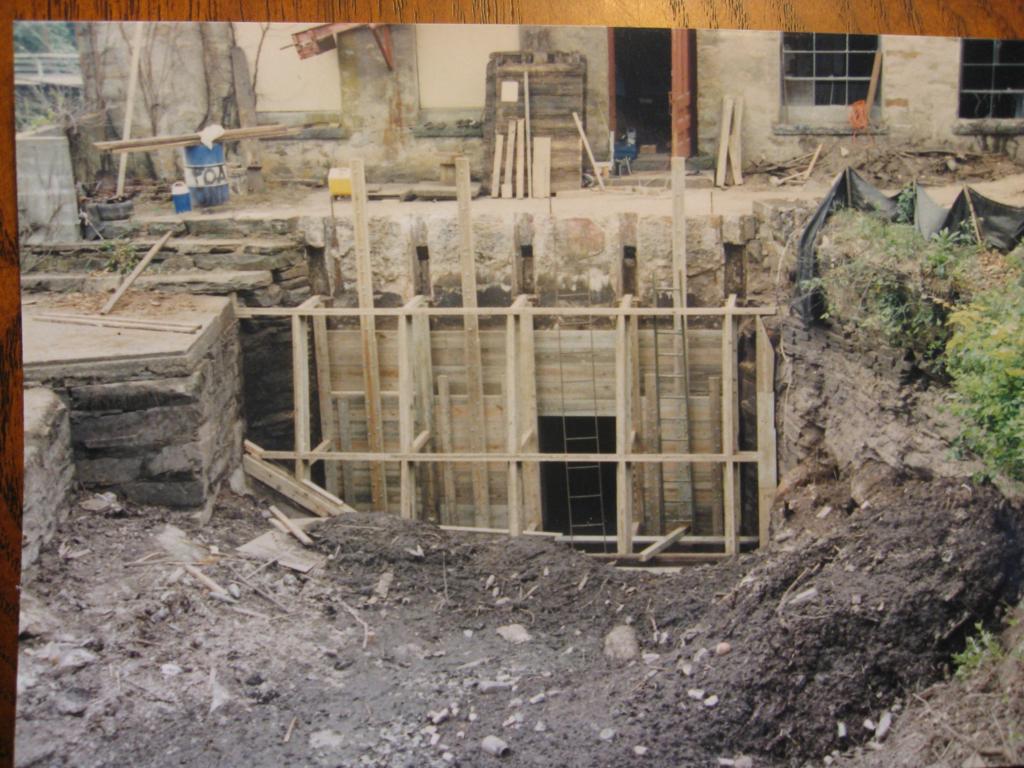

New timber intake gates and trash rack structure built by SHI for Glen Falls project.

|

Click photo to enlarge,

use back button to return to page |

|

Woodstock, CT High School

student Riley S. did a class project on hydropower. In order to understand

some of the tasks involved we had her help rake the trash racks! |

Click photo to enlarge,

use back button to return to page |

Surplus turbines, generators, hydraulic controls and switchgear purchased by Summit Hydropower for a hydroelectric project in Connecticut.

|

Click photo to enlarge,

use back button to return to page |

|

Glen Falls hydro project planned for redevelopment by SHI. |

Click photo to enlarge,

use back button to return to page |

View of propeller looking

upstream, approx. 10' diameter, 4 blades. |

Click photo to enlarge,

use back button to return to page |

|

Beginning of blade seal

replacement job at blade trunion, September 2009. |

Click photo to enlarge,

use back button to return to page |

Installation of new blade seal

with brass crescent section removed. |

Click photo to enlarge,

use back button to return to page |

|

Summit Hydro

owner Duncan Broatch surveying cross sections in river for Collinsville

Lower Fish Transportability Study, February 28, 1991. |

Click photo to enlarge,

use back button to return to page |

Mini generator

being rigged for removal to replace bearings, 80 kW.

|

Click photo to enlarge,

use back button to return to page |

|

Mini turbine at

Wyre Wynd Hydro being removed for servicing, August 2010. |

Click photo to enlarge,

use back button to return to page |

Drain gate stems

being water sand blasted by Rick to prepare surface for epoxy coating,

August, 2010. |

Click photo to enlarge,

use back button to return to page |

|

Mini turbine

being placed on truck for transport to shop to replace bearings. |

Click photo to enlarge,

use back button to return to page |

Drain gate stems

were coated with one coat of zinc primer then two coats of moisture cure

epoxy. Yes, Bob and Rick are identical twins.

|

Click photo to enlarge,

use back button to return to page |