|

Click photo to enlarge,

use back button to return to page

|

Adam installing hub after

rehabilitation

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

New turbine bearing and

half of oil sump installed.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Original stub shaft that

was replaced due to cracks visible in radius area. Flange diameter = 4'.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Water fairing was cut and

modified to make it detachable so that hub could be moved upstream six

additional inches to allow hub removal

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Draft tube and shaft

looking upstream after sand blast and 4 coats of Belzona immersion epoxy

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Gary Lee of Lee

Mechanical, Inc. making adjustments during spherical bearing install.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Donny applying torque to

shaft bolts

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Donny and Adam installing

seal carrier

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Bob and Chris working on

wicket gates. Think of them as a radial Venetian blind. They control

water flow to the turbine.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Refurbished seal carrier

with new seals

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Runner hub after

refurbishment with new stub shaft

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Bearing/seal carrier

housing showing new stainless drain piping

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Duncan installing a

(voluntary) fish protection device in draft tube

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

View of runner hub before

removal for stub shaft replacement job, October 2013.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Runner hub and cracked

stub shaft being removed

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Runner being hoisted out

of powerhouse. End of stub shaft shows the blade operating shaft which

moves longitudinally to adjust pitch of the runner blades.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Runner hub being placed on

cribbing in yard.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Wicket gate outer trunnion

housings fitted with new seals and spherical bearings ready to be

reinstalled

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Application of Belzona

1121 Super XL-Metal and 1341 Supermetalglide on cavitated area

immediately downstream of runner

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Refurbishing Jewett City mini turbine in Rawson Mfg. shop in Putnam, CT, February 2006. Black lab "Truffel" inserted for scale purposes only.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Workshop inside powerhouse

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Interfacing for datalogger and PLC programming.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Allis Chalmers Kaplan turbine

Return to

Top

|

|

Click photo to enlarge,

use back button to return to page

|

Siemens synchronous generator

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Mini turbine/generator providing minimum flow requirement

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Disassembly of Jewett City turbine servo piston to replace aged o-rings

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Forebay showing trash racks and trash rake system

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Trash rack support beams were water blasted (250,000 psi), sand blasted, epoxy primer, 3 coats epoxy topcoat.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

New galvanized trash racks being hoisted into place after removal of old corroded racks.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

SHI employee Bob shows newly installed first trash rack panel with access hatch removed.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

New trash racks in position, trash rake is near bottom position, access man hole visible.

Return to

Top

|

|

Click photo to enlarge,

use back button to return to page

|

SHI employee Bob services mini unit head gate.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

New galvanized trash racks moving into position assisted by SHI owner Duncan.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

new trash rack/trash rake/conveyor system installed by SHI.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Blasting and epoxy coating turbine throat ring and wicket gates.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Switchgear with new Beckwith protective relays.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Tailrace showing tailgate gantry system.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Intake showing trash racks.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

SHI designed oil pump/filter system.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Servo piston which controls blade movement.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

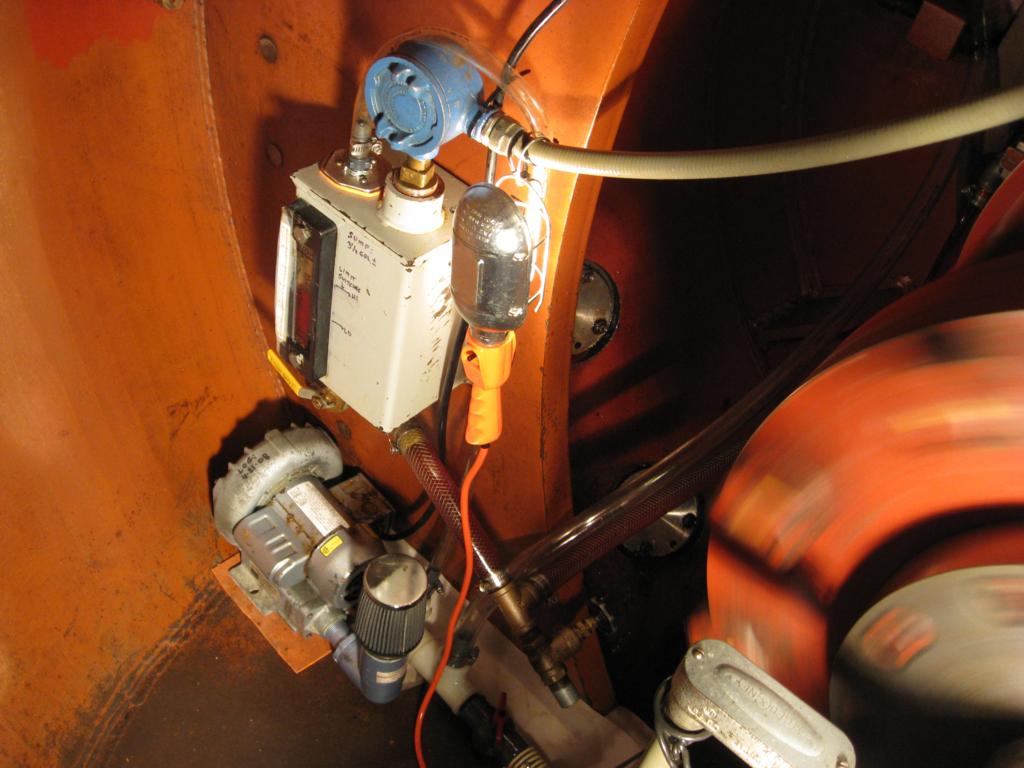

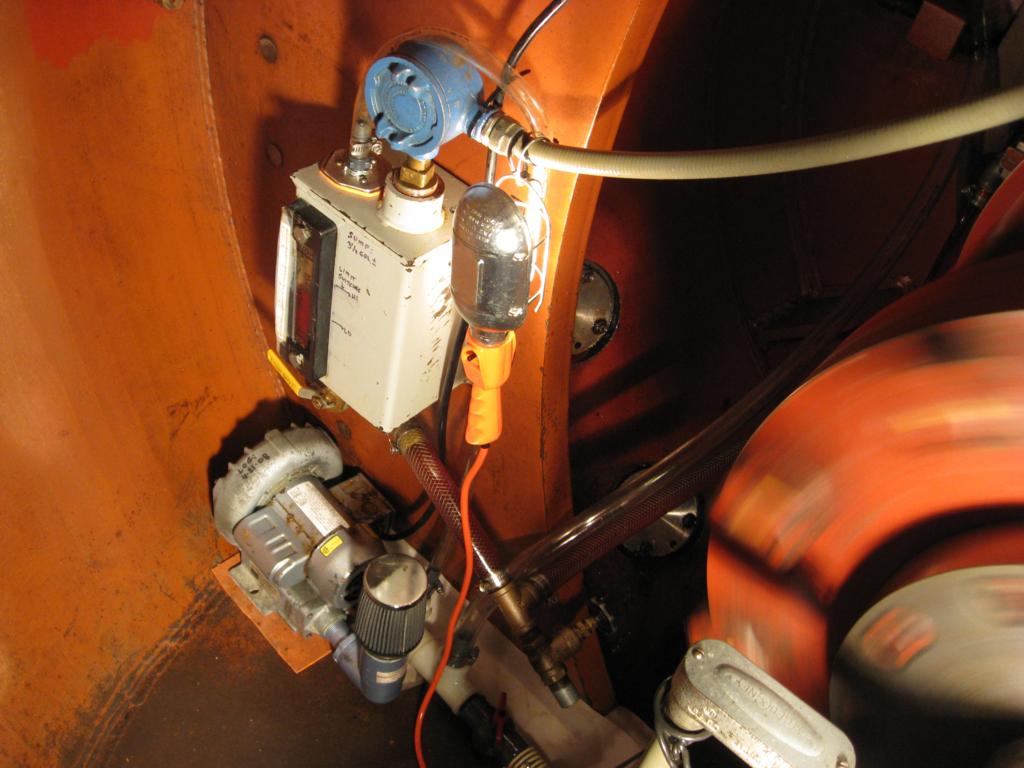

|

SHI designed regenerative blower system which eliminates seal leakage.

Return to

Top |

|

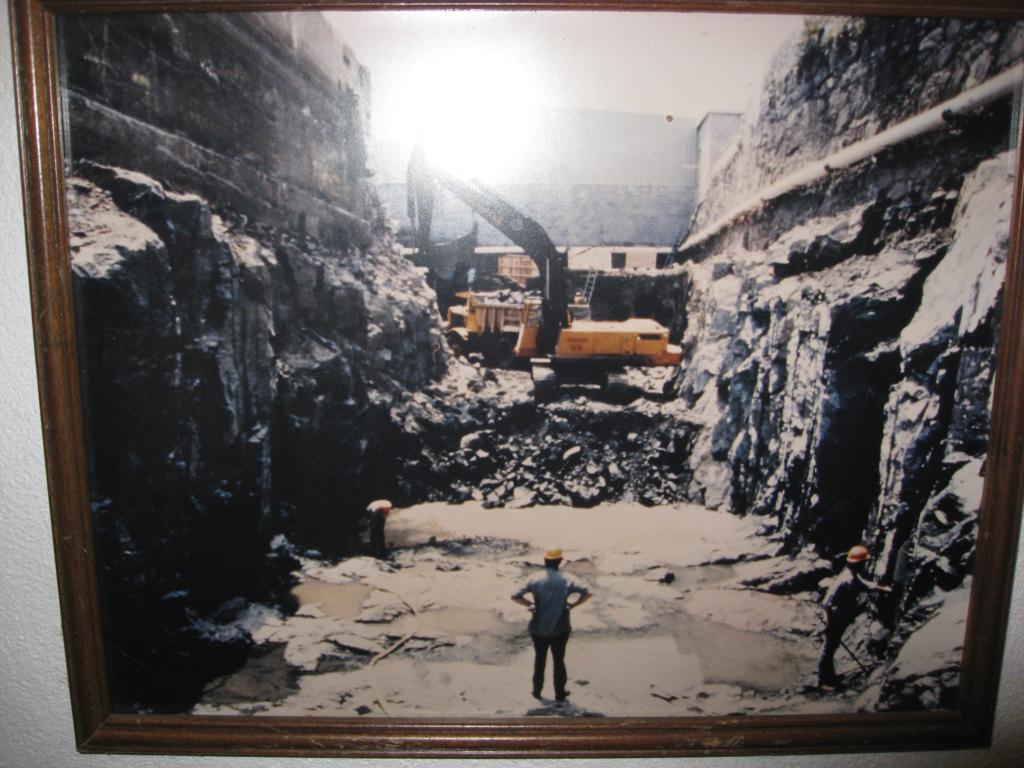

Click photo to enlarge,

use back button to return to page

|

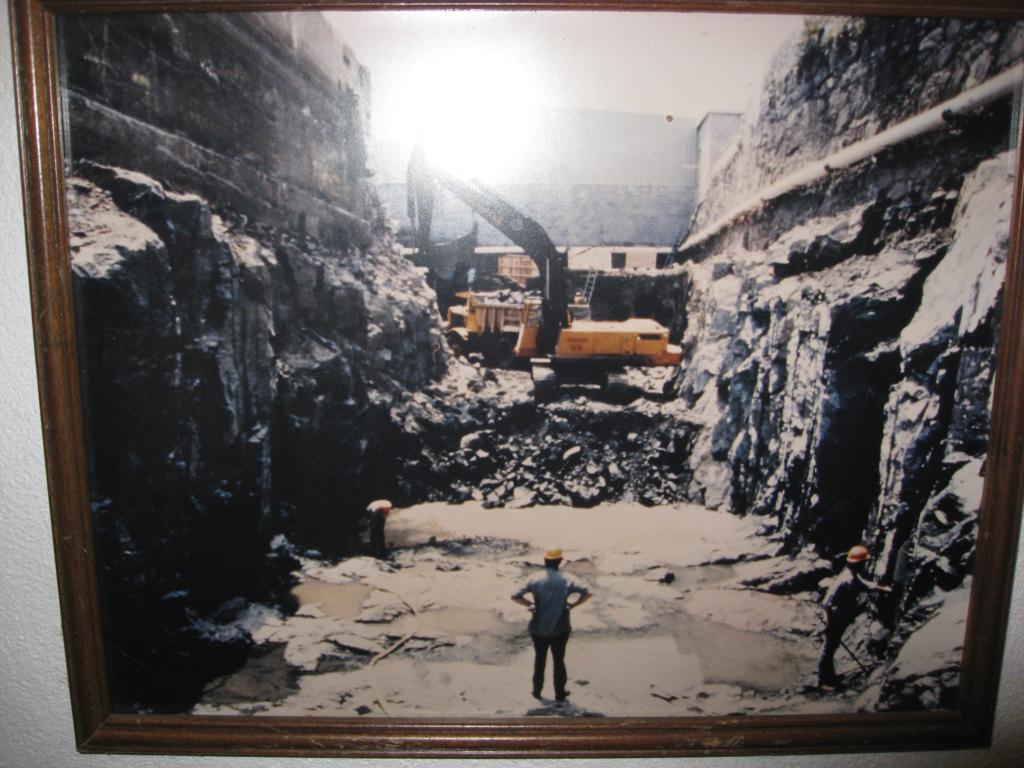

Bedrock excavation for powerhouse construction circa 1983. Man inserted for scale purposes only.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Powerhouse construction illustration extensive rebar reinforcement and generator pit.

Return to

Top

|

|

Click photo to enlarge,

use back button to return to page

|

Powerhouse construction showing draft tube fabrication.

Return to

Top |

|

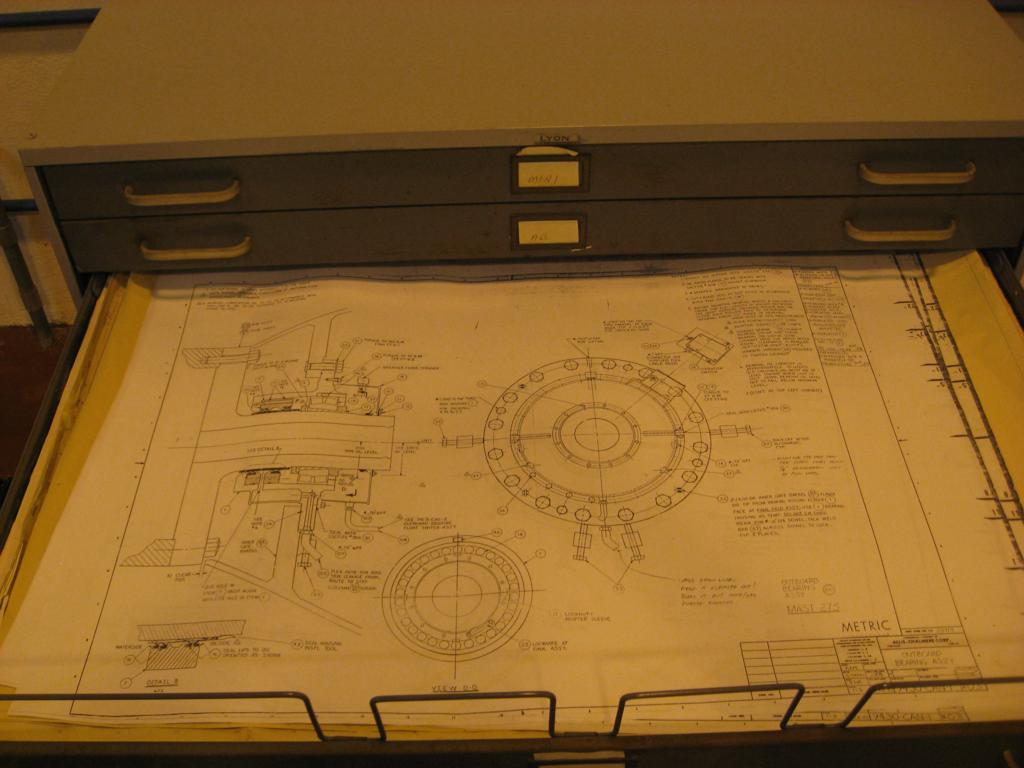

Click photo to enlarge,

use back button to return to page

|

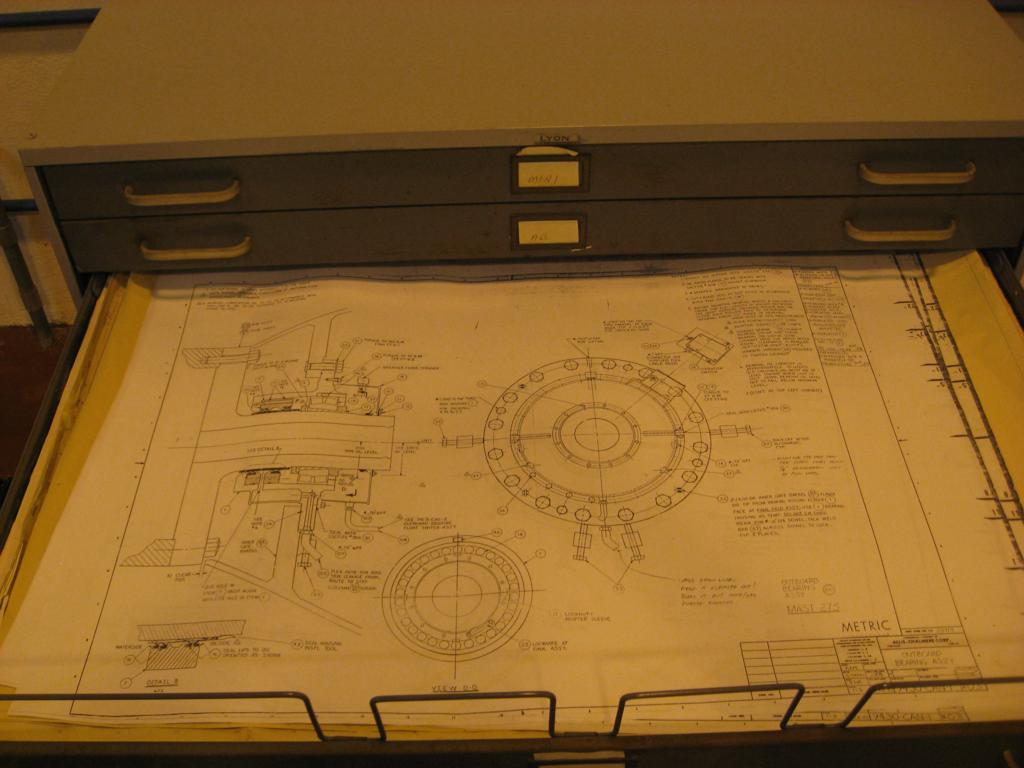

Typical engineering drawing showing upstream bearing design.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Wicket gate hydraulic actuator and control ring.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Interior of powerhouse looking upstream.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

500+ page logbook contains entries of notes for every maintenance/repair task performed.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Two 7HP dewatering pumps and control system designed and installed by SHI.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

SHI owner Duncan redesigned switchgear control system and eliminated half of the relays.

Return to

Top |

|

Click photo to enlarge,

use back button to return to page

|

Forebay, five 10-foot X 10-foot head gates, and 333 acre impoundment.

Return to

Top |